Button-Up Red Flags: What Luxury Brands Hope You Won't Notice

Watch the Video | Shop Button-Ups | Shop Button-Ups for Larger Busts

Everyone expects flawless construction from Bottega Veneta. But I found fundamental pattern-drafting failures in $1,500 shirts while $150 alternatives get the basics right. Here's what separates thoughtful construction from expensive mistakes, regardless of price point.

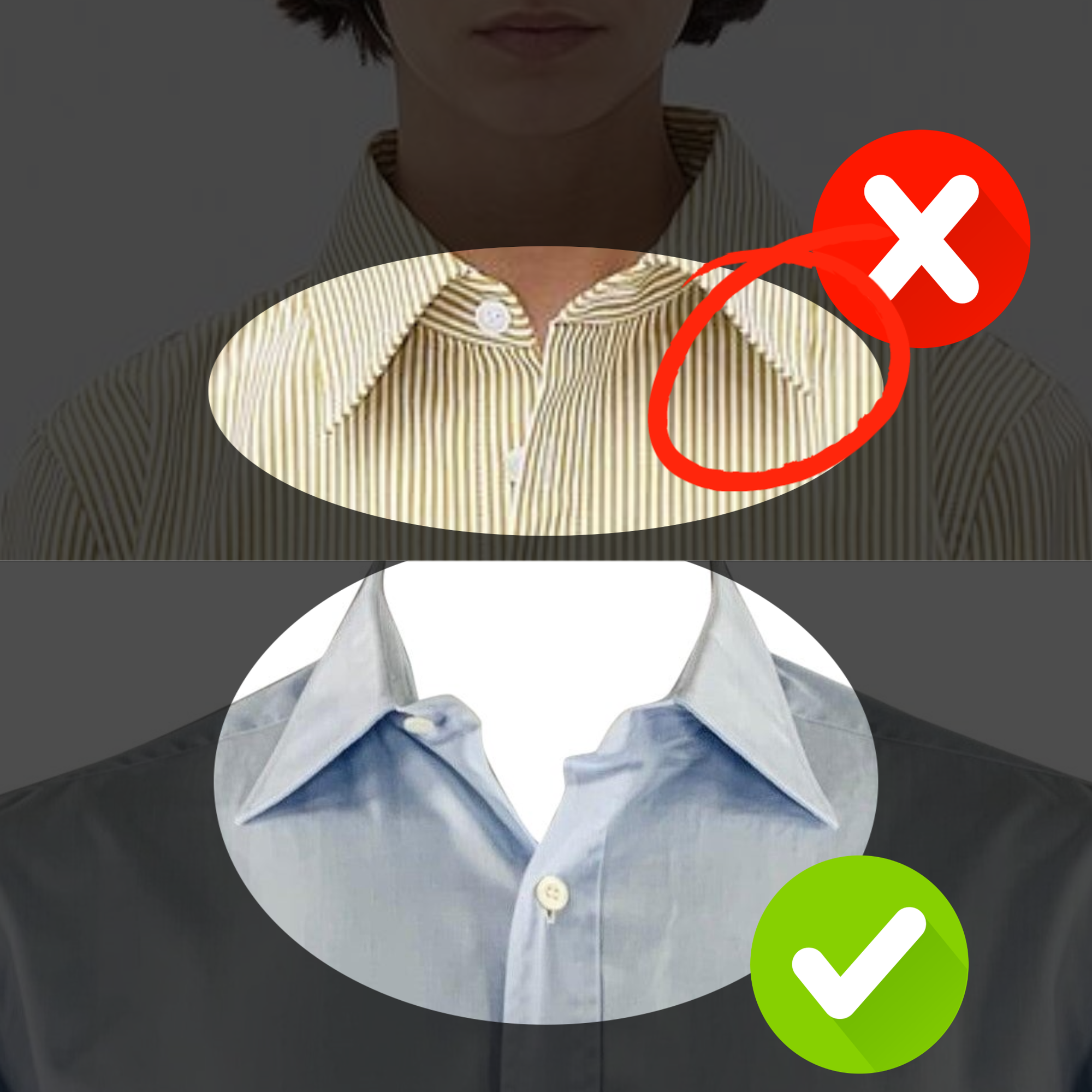

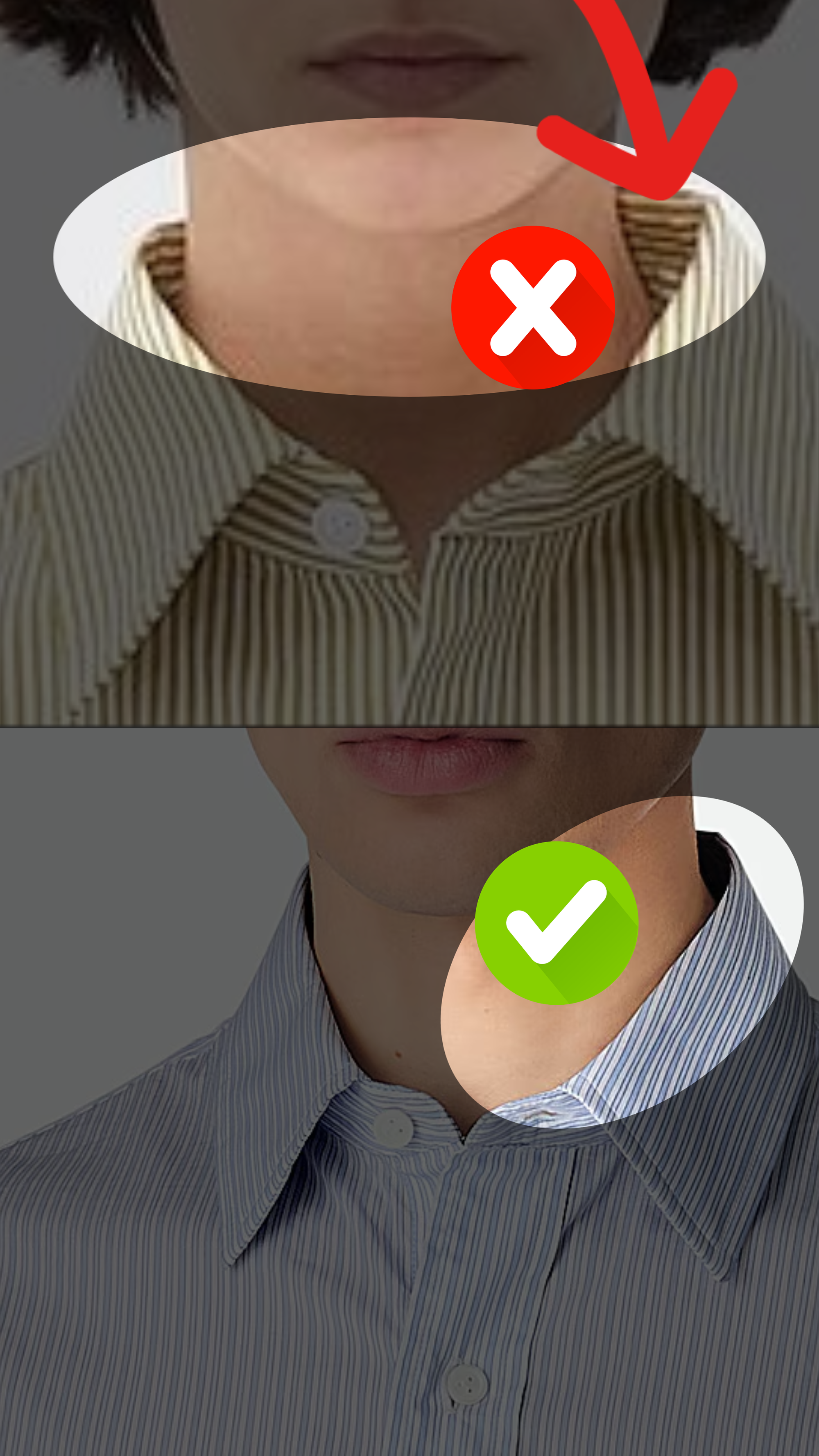

1. The Collar Shape Test

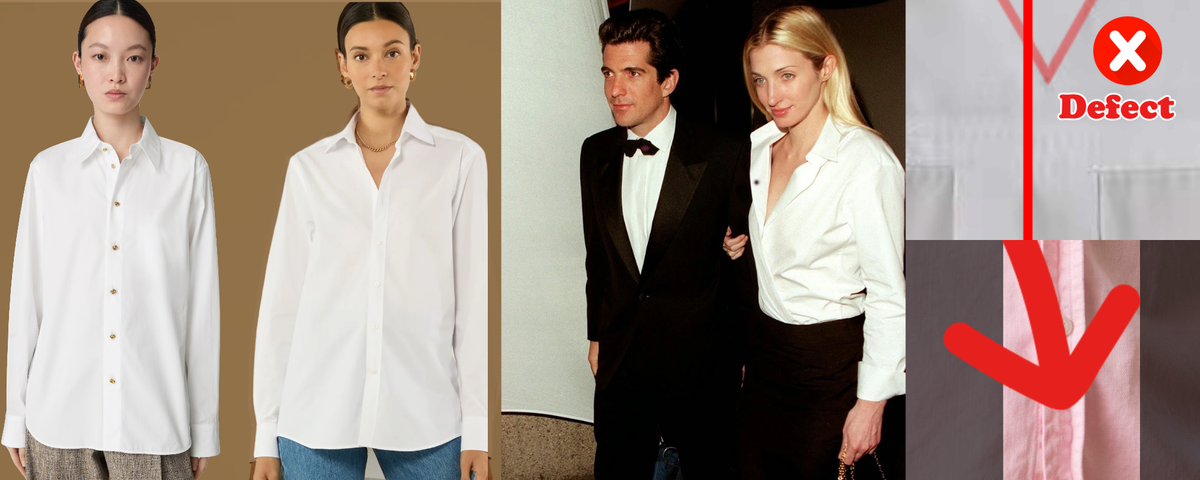

Bottega's shirt, collar point comparison, Charvet shirt

A well-constructed collar should have points that lie relatively flat against your chest when the shirt is unbuttoned. Not perfectly flush – body shape creates natural variation – but they shouldn't hover inches away from your body like they're trying to fly off.

Bottega Veneta's $1,270 cotton shirt fails this test spectacularly. The collar points lift far from the chest, creating awkward gaps that no amount of styling can fix. This isn't a defect or one-off quality control issue – it's a pattern drafting failure that shows up consistently across their product photography.

What's causing this hovering effect? The collar band doesn't follow the natural curve from neckline to chest. The pattern lacks proper collar roll allowance – the extra fabric needed for the collar to transition smoothly from neck to body. When you combine inadequate roll allowance with possibly too-stiff interlining, you get collar points that stick out rather than drape.

Compare this to how traditional shirtmakers like Charvet or Turnbull & Asser handle collar construction. Their collar points follow the body's contours. The collar band curves to accommodate the transition from vertical neck to horizontal chest plane. Even on preloved Turnbull & Asser shirts selling for under $20, the collar construction holds up because the pattern was drafted correctly from the start.

This matters because it reveals whether the manufacturer actually did proper fitting and sampling, or just copied a pattern without understanding the engineering behind it. A collar that doesn't sit right isn't something you can fix by sizing up or down – it's built into the garment's DNA.

2. The Placket Durability Test

Frank & Eileen shirt new; the placket caving; similar shirt preloved – the placket folds onto the buttons

The button placket – that center strip where your buttons and buttonholes live – should maintain crisp edges that age gracefully. Proper construction requires interfacing applied to the entire placket area, secure edge finishing, and topstitching that actually stabilizes the fabric.

Frank & Eileen's "relaxed" aesthetic appears to skip these steps. Their $288 Eileen shirt shows visible rippling along the placket edge even in brand photography –before anyone's worn it. After wear, preloved examples reveal the full extent of this construction shortcut: the fabric collapses around buttons, creating a "sandwiching" effect where excess fabric folds up against the buttons.

COS shirt; same COS shirt, preloved; COS' button placket stays much more crisp than Frank & Eileen's

COS' button plackets hold a sharp structure without excessive rigidity. Their white shirts maintain crisp plackets even in preloved condition because they've built in the structural support the fabric needs. The edges stay defined, and the whole placket holds its line, giving the shirt definition even when it's not ironed. This isn't about formality or stiffness. It's about engineering fabric to perform its function over time.

3. The Button Gap Design Choice

Absent buttons on shirts from TWP, Veronica Beard, and L'Agence